Jenny LCD 3D printer user

guide

1. Check

1.2 Check the components

1.2 Check the components

Please check the printer when express

hand it to you. Make sure there is no scratch, damage or distortion, etc.

Please check if all components are well

packed in the box. Please contact us a.s.a.p. if there is any problem.

2. Preparation2.1 Remove foamed plastics.

2.2 Uplift the Z axis

2.2.1

Insert the power plug back on the printer.

2.2.2 Turn on the printer.

2.2.2 Turn on the printer.

2.3 Remove the screen cover

2.4 Settle the resin tank

Fix

the resin tank by four M5 black screws removed from last step at four angles.

2.5 Fix the build platform

2.5 Fix the build platform

2.5.1

Block the build platform

2.6 Platform leveling

2.5.2

Fix the platform with screw nut

2.5.3 Release platform direction

adjusting screw

2.6 Platform leveling

2.6.1First,

click” back to zero” and make sure the platform is on the top.

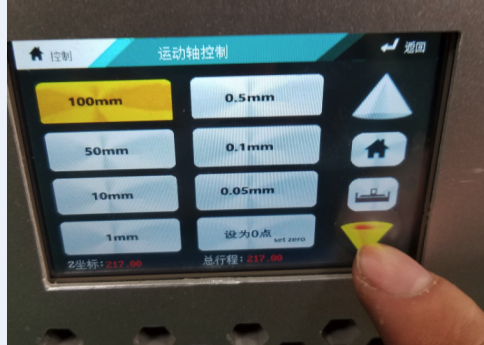

2.6.2

Choose100mm and move down

2.6.3

Choose 50mm and move down

2.6.4

Choose 10mm and move down four times. The platform should be moving down 190mm finally.

2.6.5

Continue adjusting and confirm the zero

When

platform is stick on the resin tank bottom, the adjusting is finished.

2.6.6

Confirm the zero

2.6.7

Tighten the screw and fix the platform

2.6.7

Finally, click back to the original zone

LAN IP confirms:

Insert

cable into Jennybox, and you can use computer, phone or pad to find a equipment

called jennybox. Open IP in your browser.

Check《Nanodlp

JennyPrinter special User guide》for more

information.

2.9 Print

finished and cover resin tankHand

the platform for 5 minutes and let the liquid resin drop down.

Cover

the resin tank with protective cover

Check《Jenny post

curing chamber and post processing User guide》for

more information.

Comments

Post a Comment